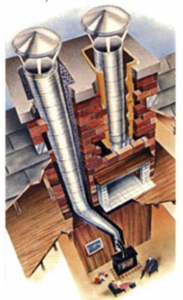

The flexible flue liner system

A stainless steel flexible flue system is a safe and cost-effective way of using the existing flue. It is used within your existing flue to “re-line” it.

Re-lining the flue with a new flue liner has many benefits involving safety and efficiency. The owner of Blazing Burners – Damian – has written a blog on this. Click here for the reasons why we choose to re-line existing flues.

There are many manufacturers of these flexible flue liners. Each one produces two types of liner.

One type is used if you intend to burn wood (only permitted on a wood burning stove). The other type is used is you intend to burn wood and smokeless fuel – referred to as multi-fuel (permitted on a multi-fuel stove).

The two types of liner are classified by the grade of stainless steel used – either 316L or 904L.

316L = wood burning purpose

904L = multi-fuel burning purpose

The 904L liner is more expensive, is constructed of a superior grade stainless steel, so it can withstand the higher temperatures generated from the smokeless fuel, thus having a greater resistance to the excess heat. For more information on the pros and cons of both wood and multi-fuel click here.

The flexible flue liners are cylindrical in shape making them easier to clean and are typically 5” or 6” in diameter, which will either match or closely resemble the stove’s outlet that in turn improves the stoves performance.

The liners span the full length of the chimney in one continuous piece. They attach to the cowl at the top, and the adapter at the bottom.

The liners are considered flexible as they resemble a large “slinky” and can be bent to bypass obstructions in your existing flue. Chimneys may be straight, but the flues that make up the chimney have bends and diagonal runs in them. How chimneys are built varies lots too. Often there are obstacles within the run of the flue – stones, bricks and dislodged clay liners – that have been subject to the abuse of previous fires and often misuse over the years. Sweeping a flue can easily dislodge a brick whose mortar has failed because of the corrosive by-products of burning fuel. You’ll be surprised how often we come across this! The state of an existing flue can often be in a very bad way.

If a flue is blocked, the obstruction must be cleared if the installation is to proceed. More often than not, this results in breaking into the flue, clearing the flue and then making good afterwards. As this is an unforeseen circumstance, it is considered chargeable within the industry. However, if it does not disrupt the installation and we are able to achieve our goal of completing within the day allotted, we rarely charge for this service.

The actual quality of the flexible flue liners varies significantly. There are many brands available. They can be manufactured in different ways and some are more durable than others. We consider some of these to be cheap and poorly constructed as they can tear or dent and unravel easily. We have literally seen brand new liners unravel. We have also removed many poor quality liners that have been damaged from poor use and even from being swept!

We only ever use Duraflue liners as we consider these to be constructed in the best way possible, ensuring that they are the toughest and most durable liners available in the industry. They endure the rigours of installation and continue to endure the rigours of use providing you look after them, get them swept regularly and burn the correct fuels in the correct way.

The conditional warranty that comes with Duraflue liners is a testament to their quality as they are the longest available in the industry. Click here for a youtube video on just how tough these liners are!

Once installed, we like to walk away knowing that our products are doing their job.

Flue insulation

In some instances, the flue may need insulating. This is recommended when the flue liner has lots of space around it. Insulating the flue will maintain the heat within the flue and thus will aid all by-products and composites of combustion to be expelled from your flue. The hot air will stay hot throughout the flue, and because hot air rises, it will carry all these harmful products until they are expelled from the terminal. Otherwise, the flue may get too cold and these harmful and tarring products may congregate within the flue, which in turn could lead to problems and dangers such as blockages and chimney fires.

There are two methods that we will use to insulate a flue.

The first approach involves wrapping the flue in a fireproof blanket. There are many names for this such as “Thermaflue” and “Chimwrap”. This technique is great when you have a large void such as an inglenook fireplace. The first three pictures above demonstrate this style of insulation.

The second approach uses a loose backfill incorporating either Leca or Vermiculite. Both of which are excellent natural insulators originating from either clay or rock respectively. Leca is featured above.

We will be able to advise you if your flue will need insulating.

Flexible flue liner installations – the Blazing way

We tend to start by sweeping the existing flue to clear the passage of debris. Our ladders will be set up to access the top of the chimney. The liner will be installed (from the top) using a weight and rope that is attached to the liner. The adapter is securely fitted to the liner. We regularly have to adjust the liner up and down so we often have to go up and down the ladders several times throughout the day.

We also install chimney pots if needed.

If a freestanding stove is installed, we will connect the stove to the adapter using black vitreous enamel flue pipe. Consequently, your entire flue system is sealed from the collar/spigot of the stove at the bottom to the cowl and pot at the top. This is very effective at being safe and efficient.

The stove will be “mock” installed into the fireplace and the vitreous flue pipe will need working out to ascertain what and how much is required to ensure the flue is fitting correctly and the stove is positioned in its optimum position so that air can flow around the entirety of the stove. A freestanding stove should never be “squashed” into a fireplace. It needs to breathe so that it can work properly!

A “closure plate” will be measured and fitted above the opening of the fireplace. It closes off the chimney and flexible flue from the stove and flue pipe. This has similarities to a “register plate” but is different.

The closure plate has two functions

- To prevent any chimney debris falling onto your lovely stove.

- To prevent heat from escaping up the chimney.

We use steel to form this plate and cut it on site, as every opening is different. We cut a hole in this steel plate so that the vitreous pipe can pass through it. We make sure the plate is snug fitting and looks good, and so to finish it off we paint it black. We regularly see other closure plates that we think are sub-standard!

The order in which all these components come together will be dictated by various aspects of the installation, and often by the conditions presented outside! We have the experience gained from hundreds of installations that help make our installations as efficient as possible, saving you from any unnecessary mess and inconvenience. We have regularly been called in to pick up pieces from other professionals (including fellow HETAS installers) and DIY enthusiasts. People that have performed haphazard and dangerous stove installations, and that have taken much longer time than is required, or have encountered obstacles and problems that they cannot overcome.

If you want a stove installation that will look and perform great, and that will be installed in a meticulous, safe and effective manner, contact Blazing Burners here.